DC IR vs SOC (V)

While the 3.35Ah cells mentioned in the previous email have been cycling, I have also had the INR26650-50A PLB 3.6V 4.9Ah cell cycling. After 326 cycles at 0.5C charge and 4A (the max a Cadex C7400 battery tester can do) discharge the cell is at 96% of its nominal capacity.

This cell was designed for EV and has a very long life. The manufacturer has supplied far more information than other suppliers do, fantastic. This information would be important for programming a good quality BMS making sure a battery pack attains a claimed range for the life of a vehicle or whatever product we design it into. This cell is currently being designed into a robotic device. Also very useful for simulating all of the what-if situations in applications.

The pdf is one of the best pieces of information we have had from a manufacturer. To get this level of info for other cells you have to run your own tests, which is what I have been attempting. There is plenty of data on DC IR at various temperatures and SOC, a snip of these graphs can help explain to a customer what happens when it is cold and why we may have designed in a larger capacity than they expected.

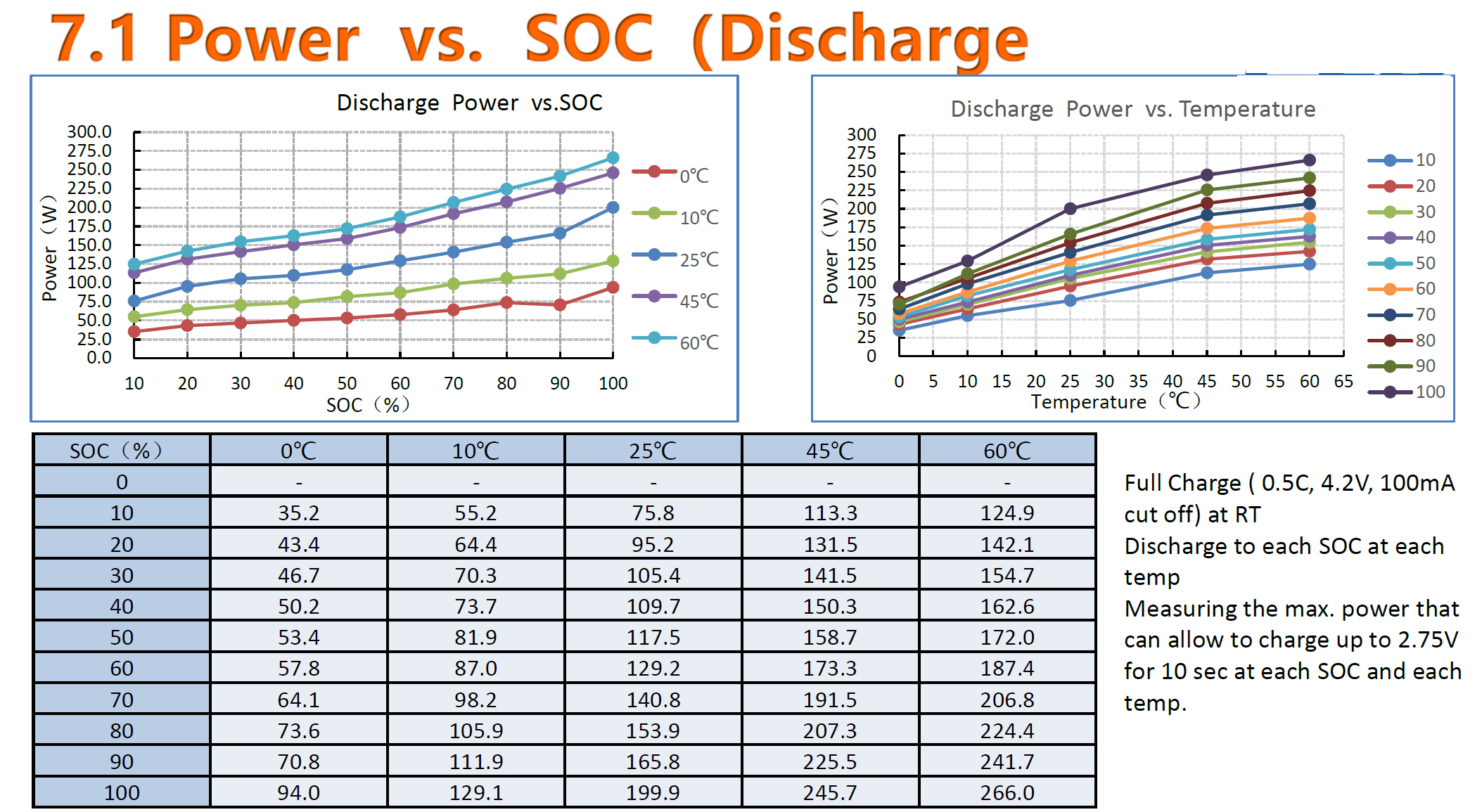

Page 10 (below) shows an array for how much power can be discharged at any SOC and temperature. More information a BMS would send a load controller so that it does not excessively stress the cells. The Lithium Balance BMS we have available can accept this data. Page 11 shows the same information but for charging.

If you have a customer that requires a long life cell, this could be the one.

If a customer needs to extend the life of any of the other cells, there are ways and the battery engineering dept. would be happy to help.